Netsudo chambers use premium materials, high-precision sensors, and top-grade components to ensure durability, accuracy, and long-term performance in all environmental testing and controlled storage applications.

Netsudo chambers use premium materials, high-precision sensors, and top-grade components to ensure durability, accuracy, and long-term performance in all environmental testing and controlled storage applications.

Netsudo Proprietory Technologies

Netsudo’s proprietary technologies are the result of dedicated engineering and innovation, tailored for precise environmental control. Our advanced systems, including temperature, humidity, and lighting solutions, are built in-house to deliver unmatched accuracy, reliability, and efficiency—setting a new standard in performance across pharmaceutical, research, and industrial chamber applications.

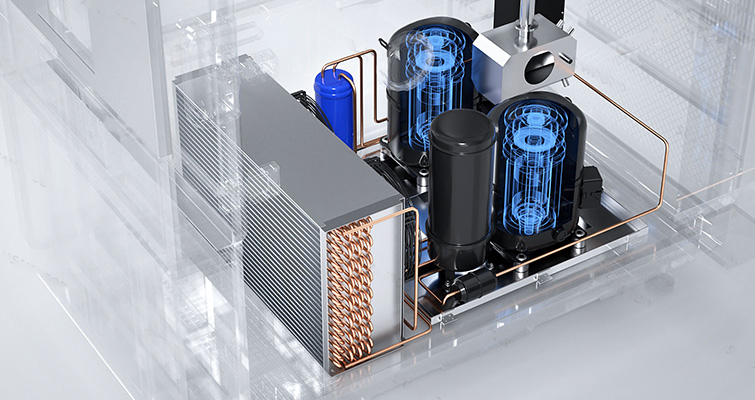

Optimized VCRS with HGBS

Netsudo’s Hot gas Bypass technology actively maintains stability, protects equipment, and optimizes energy use—making it indispensable for critical applications like pharma stability testing, BOD incubation, and thermal shock cycles Low-load temperature drift holds ±0.1°C

• Compressor wear 30% longer lifespan

• Prevents evaporator icing

• Energy use at partial load 20% less energy smart gas redirection

Netsudo HybridHumid™

Environmental test chambers require precise and stable humidity control, especially in industries like pharmaceuticals, electronics, and automotive testing. Netsudo (assuming it adopts advanced humidity systems) likely utilizes a dual-technology approach—combining boiler (steam generator) and atomizer (ultrasonic/fogging) systems—to achieve high accuracy, rapid response, and wide humidity ranges.

Illumination Technology

At Netsudo, we engineer advanced lighting systems for pharmaceutical stability testing and precision plant growth research. Our chambers deliver regulatory-compliant, high-performance illumination—ensuring accurate results, faster research cycles, and uncompromising quality.

• Option of Lighting

A. Cool White Fluorescent Lamps

B. Near-UV Fluorescent Lamps

C. Full-Spectrum LED Panels

D. Red-Blue LED Clusters

Accuracy & Precision

Netsudo technologies are engineered for exceptional accuracy and precision, ensuring stable and consistent environmental conditions. Every system is finely tuned to meet the highest standards, making our chambers ideal for critical testing and research applications.

Netsudo technologies are engineered for exceptional accuracy and precision, ensuring stable and consistent environmental conditions. Every system is finely tuned to meet the highest standards, making our chambers ideal for critical testing and research applications.

Powered by Industry-Leading Sensors

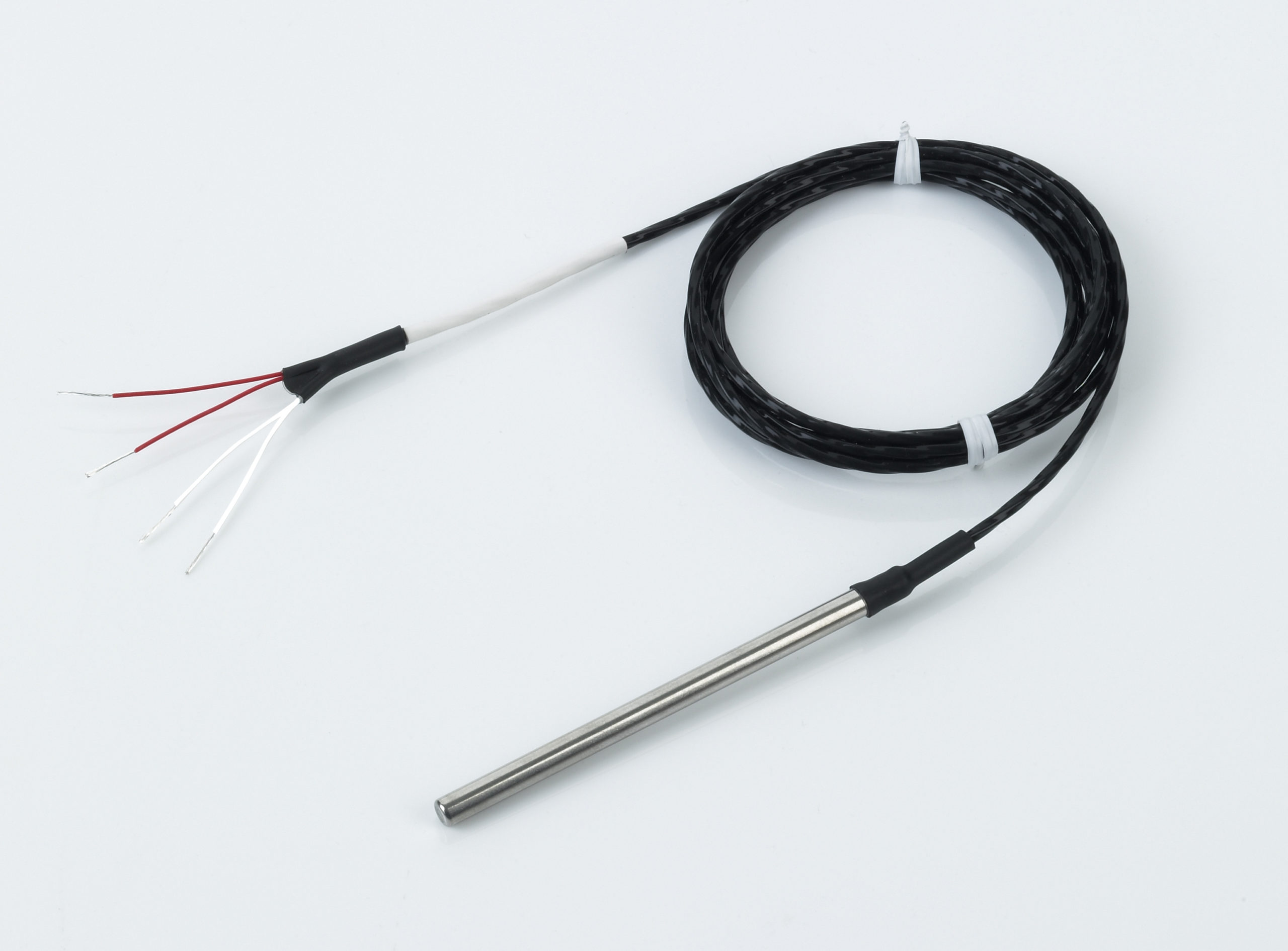

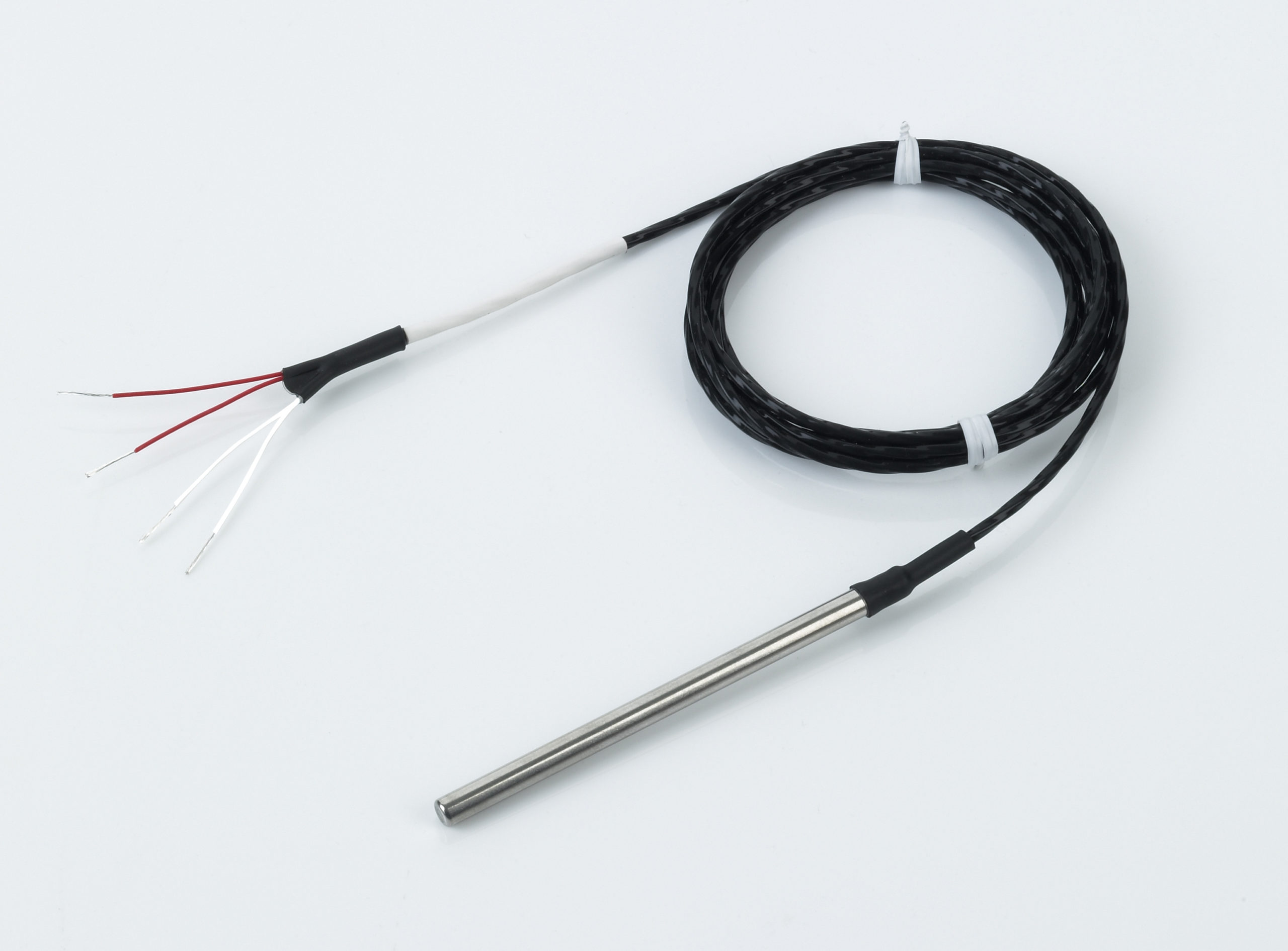

PT100 Sensor

Offers excellent accuracy, stability, and a wide temperature range for precise temperature control. Its platinum resistance provides reliable, repeatable measurements crucial for environmental chambers.

humidity Capacitive Sensor

Delivers reliable and accurate relative humidity measurements. Crucial for preventing mold, static, or material degradation by maintaining desired moisture levels

PAR Sensor

Essential for horticulture, ensuring plants receive optimal Photosynthetically Active Radiation for efficient photosynthesis and healthy growth in controlled environments.

Lux Sensor

Measures visible light intensity for general illumination control and uniformity. Useful for human comfort or non-photosynthetic light requirements

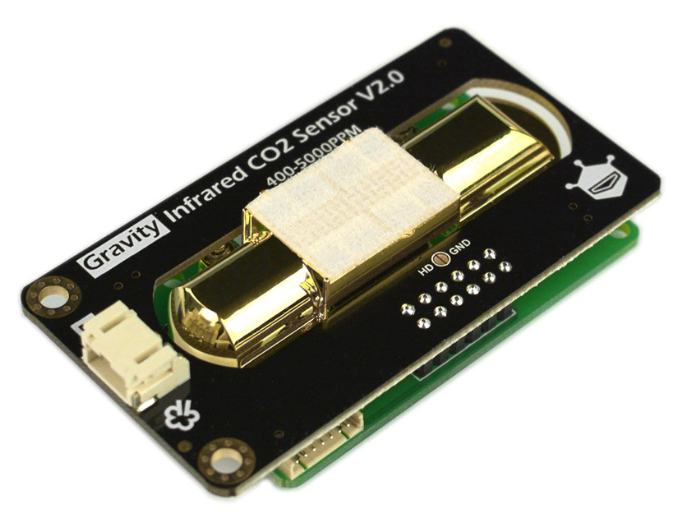

Infrared CO2 Sensor

Provides accurate, stable, and long-lasting CO2 measurements. Ideal for monitoring and controlling carbon dioxide levels for plant growth or air quality.

Zirconium Oxygen Sensor

Offers high accuracy and fast response for precise oxygen concentration control, crucial for various controlled atmospheres and combustion optimization.

Control System

Enables precise, automated environmental adjustments through sensor feedback. Features include programmability, data logging, alarms, and remote monitoring for optimal chamber performance.

PT100 Sensor

Offers excellent accuracy, stability, and a wide temperature range for precise temperature control. Its platinum resistance provides reliable, repeatable measurements crucial for environmental chambers.

Validation

Netsudo ensures 100% validation readiness through a structured compliance process built into every environmental chamber. From the Design Qualification (DQ) phase—guaranteeing blueprint-level compliance—to a digitized, risk-based Installation Qualification (IQ) that aligns with 21 CFR Part 11, EU Annex 11, ICH, IEC, ISO, GMP & FDA standards, every step is audit-ready. Performance Qualification (PQ) validates real-world reliability, while our Factory Acceptance Test (FAT) confirms all specifications are met before delivery. Additionally, NIST-traceable sensor calibration and ISO 17025-compliant reports provide unmatched precision and documentation. With Netsudo, validation isn’t a step—it’s a standard.

Netsudo Safety Assurance

Netsudo environmental chambers integrate multi-layered safety protocols to ensure fail-safe operation across pharmaceutical stability testing, plant growth studies, and extreme-condition simulations.

A. Thermal Protection

B. Electrical System

C. Power failure data Safe Mode

D. Backup refrigeration system

E. Backup humidity system

Netsudo Factory Test Report

Netsudo’s FAT process ensures every environmental chamber meets all design and functional specifications before shipment—saving time, cost, and reducing installation risks.

Design Compliance – Confirms alignment with user specs and regulatory standards

Functional Testing – Verifies reliable performance under real-world conditions

Software Validation – Ensures control systems meet 21 CFR Part 11 & EU Annex 11

Regulatory Checks – Confirms compliance with ICH, GxP, ISO 17025, and FDA

Mapping Report – Documents uniformity of temperature and humidity

Netsudo Sensor Calibration Report

Netsudo’s calibration reports deliver NIST-traceable, audit-ready documentation for all chamber sensors, ensuring your system meets the highest standards of accuracy and reliability. Each sensor is meticulously calibrated using validated procedures, supporting full compliance with ISO 17025, GMP, and FDA 21 CFR Part 11 regulatory requirements. These reports provide transparent, verifiable proof of sensor performance, offering peace of mind during audits, validations, and day-to-day operations. With Netsudo, you gain not only precision, but also documented assurance that your environmental conditions are always within specification.

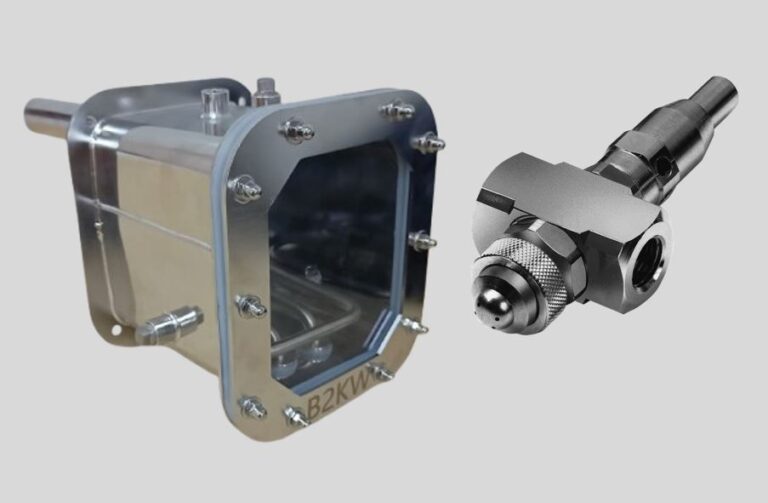

Parameters Validation

Netsudo chambers are thoughtfully designed with a dedicated validation and cable access port, equipped with a high-quality rubber plug. This feature allows seamless entry of probes, sensors, or wiring for testing and validation—without compromising the internal environment. Whether for temperature mapping, external monitoring, or third-party equipment integration, the port ensures full access while maintaining chamber seal, pressure, and thermal stability.

Environment & Sustainability

LOW GWP REFRIGERANTS

Netsudo chambers utilize low-GWP (Global Warming Potential) refrigerants to minimize environmental impact without compromising performance. These eco-friendly refrigerants align with global sustainability standards, ensuring efficient cooling while supporting green compliance and long-term climate responsibility.

DESIGN FOR SUSTAINABILITY

Netsudo designs prioritize environmental responsibility, using energy-efficient components and low-GWP refrigerants. With minimal resource consumption, recyclable materials, and reduced emissions, our chambers support long-term ecological balance while maintaining peak performance—meeting global standards for sustainable engineering in scientific and industrial applications.

LONG LIFE CYCLE & REPAIRABILITY

Netsudo chambers are engineered for long-term performance with robust materials, modular design, and accessible components. Strict quality control ensures reliability, while standardized parts and easy maintenance reduce downtime, extend lifespan, and support sustainable, cost-effective operation throughout the product’s lifecycle.

ROHS COMPLIANCE

All Netsudo chambers comply with RoHS (Restriction of Hazardous Substances) directives, ensuring they are free from harmful materials like lead, mercury, and cadmium. This guarantees safer operation, environmentally responsible disposal, and alignment with global electronic equipment safety and health standards.

DIGITAL MONITORING

Netsudo chambers feature advanced digital monitoring systems, enabling real-time tracking of temperature, humidity, and system status. With remote access, alerts, and data logging, users gain full control and visibility—ensuring precision, compliance, and proactive maintenance for every application.

ISO 14001 CERTIFIED

Our manufacturing processes are ISO 14001 certified, reflecting a commitment to continuous environmental improvement. From energy efficiency to waste management, every step follows internationally recognized standards, ensuring that Netsudo products are sustainably produced and environmentally responsible from concept to delivery.

ROHS COMPLIANCE

All Netsudo chambers comply with RoHS (Restriction of Hazardous Substances) directives, ensuring they are free from harmful materials like lead, mercury, and cadmium...

DIGITAL MONITORING

Netsudo chambers feature advanced digital monitoring systems, enabling real-time tracking of temperature, humidity, and system status...

ISO 14001 CERTIFIED

Our manufacturing processes are ISO 14001 certified, reflecting a commitment to continuous environmental improvement...

LOW GWP REFRIGERANTS

Netsudo chambers utilize low-GWP (Global Warming Potential) refrigerants to minimize environmental impact without compromising performance...

DESIGN FOR SUSTAINABILITY

Netsudo designs prioritize environmental responsibility, using energy-efficient components and low-GWP refrigerants...

LONG LIFE CYCLE & REPAIRABILITY

Netsudo chambers are engineered for long-term performance with robust materials, modular design, and accessible components...

Safety

“Safety is not an option—it’s a responsibility built into every detail.”

Netsudo chambers are engineered with a comprehensive suite of advanced safety mechanisms to ensure reliable, risk-free operation in demanding environments. From over-temperature protection and emergency stops to fire-resistant materials and sensor fault detection, each feature meets global safety standards—safeguarding people, processes, and performance.

Circuit Breaker (ELCB)

Earth Leakage Circuit Breakers (ELCBs) detect current leaks and immediately disconnect power to prevent electric shock and fire risks. These devices are in line with IEC 60947-2 and IEC 61008, which govern the design and function of residual current-operated circuit breakers. Compliance ensures electrical safety in high-sensitivity environments, such as laboratories and cleanrooms.

Over Temperature Protection (OTP)

Over-temperature protection (OTP) safeguards the system by shutting it down if internal temperatures exceed predefined limits. This feature is vital in preventing overheating, which could lead to fires or equipment failure. OTP systems often comply with IEC 61010-1 (Safety requirements for electrical equipment for measurement, control, and laboratory use), which mandates thermal safety mechanisms for laboratory and industrial equipment.

Emergency Stop Button

The emergency stop button allows for immediate manual intervention, instantly halting all operations during an emergency. It must be accessible, clearly marked, and fail-safe. This safety control complies with ISO 13850 (Safety of machinery — Emergency stop function) and IEC 60204-1, ensuring proper functionality and operator protection.

Independent Temperature Limit Control

This is a secondary, stand-alone controller that acts as a backup to the main system, shutting down heating elements if unsafe temperature levels are approached. It is typically required under EN 60519-2 and IEC 60730, which specify safety requirements for temperature control systems, especially in thermal equipment like ovens, chambers, and incubators.

Sensor Fault Detection

Sensor fault detection monitors the integrity and connectivity of temperature and humidity sensors. Upon detecting anomalies or disconnections, the system alerts the operator or safely shuts down operations. This feature aligns with ISO 13849-1 and IEC 61508 (Functional safety of electrical/electronic systems), which emphasize fail-safe sensor architecture and fault diagnostics.

Visual and Audible Alarm System

These alarms provide immediate feedback to operators in the event of critical errors like overheating, power failure, or sensor faults. The alarms must comply with IEC 60073 and IEC 60204-1, which outline standardized colors, sounds, and signal prioritization to ensure proper human-machine interaction in industrial settings.

After Sales Support

We offer excellent after-sales service to ensure uninterrupted performance of your equipment.

A skilled and certified Netsudo technician is assigned for scheduled maintenance.

Routine checkups are carried out every 6 months or annually, depending on the product.

Each component is inspected individually for early issue detection and optimal performance.

Preventive maintenance helps avoid breakdowns and extends system lifespan.

Ensures a stable and controlled environment is always maintained for consistent operation.

“Happiness is a by-product of an effort to make someone else happy.”

– Gretta Palmer